Nuclear AMRC researchers are developing a new approach to helping manufacturers reduce energy use and emissions, through AI-assisted digital twins of workshop equipment. AI technical fellow Dr Dattatraya Parle and software developer Noel Padgaonkar explain how they’re building a plug-and-play platform for SMEs.

The UK was the first major economy to commit to reaching net zero emissions of greenhouse gases by 2050, presenting a challenge to organisations in every part of the economy. Manufacturing companies of all sizes will need to decarbonise their own operations, but often lack the tools to do so effectively.

To help small and medium-sized manufacturers meet the challenge of reducing their emissions, we are working to build an open-source plug-and-play digital twin platform which will allow any company to monitor and manage their energy use.

To meet user needs, the platform needs to provide a range of features including energy monitoring and carbon reduction, asset monitoring and management, process optimisation and operational efficiency, data analysis and modelling, and data visualisation – while being affordable and easy to operate for small companies with little experience in such technologies.

We started by seeing what’s currently available, reviewing 30 commercial digital twin platforms and 12 open-source alternatives. We concluded that off-the-shelf platforms do not provide a plug-and-play solution for SMEs, and are now developing a tailored platform for emissions reduction which will be easier for SMEs to implement.

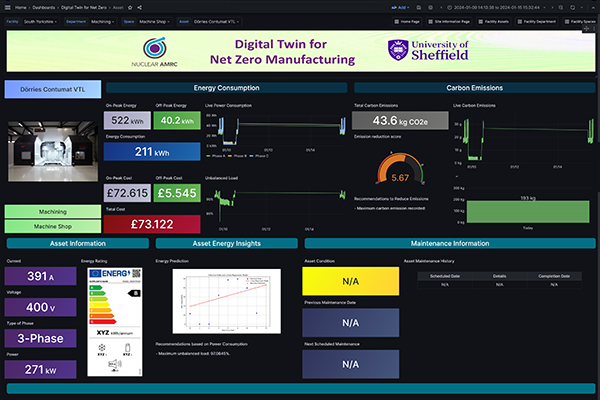

Our platform follows a hierarchical approach, beginning from the organisation and ending at the asset. This will allow the manufacturer to monitor their facility assets at every layer, getting a detailed insight into how the facility and its assets are performing with respect to energy consumption and carbon emissions.

We have now developed a sample sandbox using open-source technologies, and tested it using data from equipment at our own facilities. After a first demonstration to the Nuclear AMRC’s research board of industrial members, who are funding this initial development, we have presented this at the Smart Factory Expo in Birmingham, and the Digital Engineering in Nuclear Technology Conference in the US.

These demonstrations have garnered strong interest from manufacturers, and we are now in discussions about potential collaborations in the UK and abroad.

Our platform is designed to empower manufacturers in effortlessly implementing a digital twin solution for asset monitoring, streamlining the journey towards reducing emissions with the utmost simplicity.

On the hardware side, we achieve simplicity through the deployment of an array of sensors. The manufacturer only needs to input essential details into the configurator tool, to automatically create comprehensive elements such as data models and interfaces.

A data interface showcases essential information, with the main screen displaying energy and carbon data for all the user’s facilities. The interface also provides an emission reduction score, indicating progress along the road to net zero emissions.

The user can navigate to detailed insight on energy and carbon emissions across all their assets, departments and spaces, and effortlessly switch between facilities.

The digital twin provides comprehensive details of a specific asset, encompassing fundamental energy and carbon usage, along with predictions derived from AI and machine-learning models. Manufacturers can also delve into deeper insights such as asset power requirements, energy rating, maintenance history, and the monitoring of additional sensors.

Our proposed solution will empower manufacturers with a seamless journey towards net zero emissions, leveraging user-friendly hardware deployment, intuitive interfaces, and detailed insights across assets, departments, and spaces for informed and sustainable decision making.

We are also looking at integrating our digital twin platform with the Manufacturing Energy Toolkit programme developed by the High Value Manufacturing Catapult, which will allow it to be easily adopted by SMEs working with any of our sister centres in the full range of manufacturing sectors.

If you are interested in using our digital twin platform to help you with energy saving, carbon accounting, and sustainability, please do get in touch by emailing us at d.parle@namrc.co.uk or noel.padgaonkar@namrc.co.uk